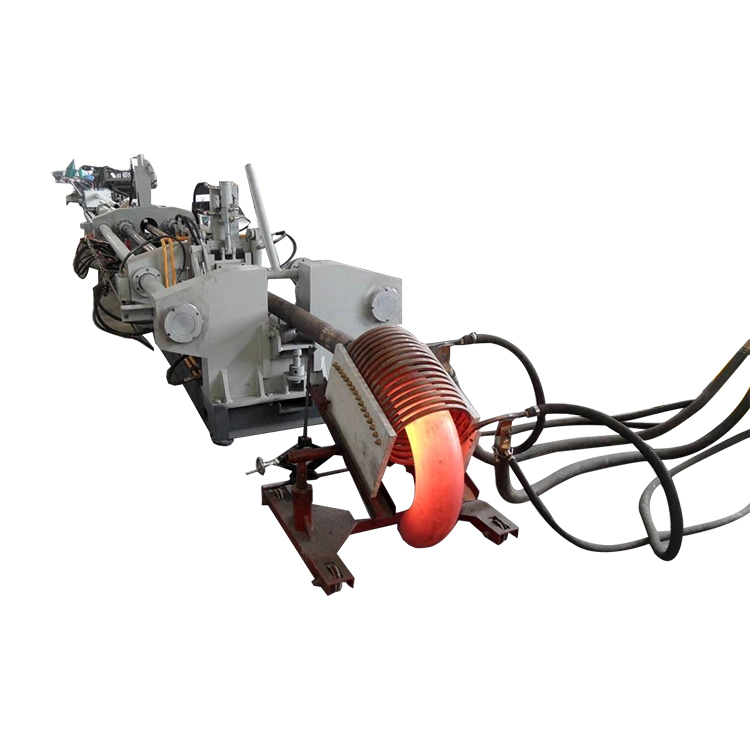

Elbow machine is a device commonly used in pipe systems to change the flow of pipes. It consists of a series of components, including elbow body, flange, support frame, hydraulic cylinder and control system. The structure and working principle of the elbow machine will be described in detail below.

1. Structure of elbow machine:

The main structure of the elbow machine includes elbow body, flange, support frame, hydraulic cylinder and control system.

Elbow body: Elbow body is a curviline-shaped pipe part, usually made of carbon steel, stainless steel, or alloy steel. It has a certain bending radius and Angle for changing the flow direction of the pipeline. According to the need, the Angle of the elbow body can be 90 degrees, 45 degrees, 30 degrees, etc.

- Flange: The flange is the part that connects the elbow body to the pipe and is usually made of steel. It has the function of fixing the elbow body and the pipe and can be fastened together by bolts.

- Support frame: The support frame is used to support and fix the elbow machine. It is usually made of steel and can be adjusted and fixed as needed to ensure the stability of the elbow machine.

- Hydraulic cylinder: The hydraulic cylinder is the power source of the elbow machine and is used to control the rotation of the elbow body. The hydraulic cylinder is composed of a hydraulic cylinder, a piston and a hydraulic power device. The hydraulic power unit drives the hydraulic cylinder through the hydraulic oil so that it can control the Angle adjustment of the elbow body.

- Control system: The control system is the core part of the elbow machine and is used to control the work of the hydraulic cylinder. It is usually composed of an electrical control cabinet, a sensor and a hydraulic control valve. Through the control system, the Angle and speed of the elbow machine can be accurately controlled.

2. Working principle of elbow machine:

The working principle of the elbow machine can be simply summarized as: through the role of the hydraulic cylinder, the rotation of the elbow body is controlled and the flow direction of the pipeline is changed.

The specific working process is as follows:

- First, the hydraulic oil is delivered to the hydraulic cylinder through the control system, so that the piston inside the hydraulic cylinder moves outward. The movement of the hydraulic cylinder can be realized through the hydraulic control valve and the hydraulic power device.

- When the piston of the hydraulic cylinder moves outward, it is connected with the elbow body. Through the movement of the piston, the force applied by the hydraulic cylinder causes the elbow body to start rotating.

- When the elbow is rotated to the desired Angle, the control system stops the movement of the hydraulic cylinder and maintains the position of the elbow.

- During the whole working process, the control system will constantly monitor the Angle and position of the elbow body through the sensor, and make timely adjustments to ensure the accurate and stable work of the elbow machine.

The working principle of the elbow machine is simple and effective, and the rotation of the elbow body is controlled by the movement of the hydraulic cylinder to achieve the change of the flow direction of the pipe. It has the advantages of simple structure, convenient operation, accurate adjustment, etc., and is widely used in pipeline system to meet the needs of different fluid transportation.

For more knowledge about elbow machine, please pay attention to our website: http://www.fitting-equipment.com

|