| Transport elbow machine skills?

The elbow machine produced by the company mainly produces various types and materials of elbow pipe products. The elbow pipe fittings produced by the elbow machine can improve the production efficiency and reduce the labor intensity. The bend machine can help to bend the radius of the bend processing, the use of the bend machine in the process of making the bend pipe can provide the operator to produce and control the bend and improve the quality of the elbow product, reduce the production cost of customers, and greatly improve the elbow processing skills.

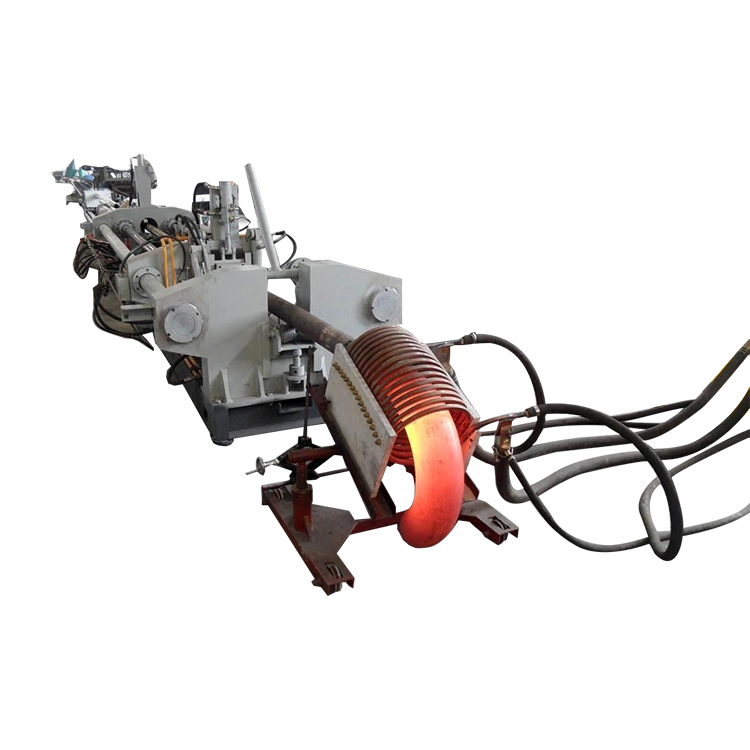

When ordering elbow machine, customers will know that elbow machine is an advanced technology for making elbow pipe fittings, that is, elbow machine is the main equipment used to make elbow pipe fittings. The radius of elbow pipe fittings produced by elbow machine is divided into long radius elbows and short radius elbows. Two kinds of elbow pipe products Our company's elbow machine can produce the elbow products ordered by customers at one time, which shows that the elbow machine is the main equipment for making elbow pipe products. In the production process is accepted in the medium frequency heating, expanding the diameter, bending molding.

Hot push elbow is based on the material of the metal to change the manufacturing process and choose the elbow machine equipment produced by our company, elbow machine is divided into medium frequency elbow machine, cold push elbow machine two kinds. Two kinds of elbow machine medium frequency elbow machine mainly produces carbon steel, alloy steel and other materials of elbow, cold elbow machine mainly produces stainless steel elbow pipe products.

The elbow machine comprises a frame, a working table, a side working table, an oil press, a fuel tank, an electrical box and a control panel, and also includes a forming mold, a drawing device and a stripping device. The frame is a whole frame structure. The hydraulic press comprises a vertical hydraulic press arranged vertically between the columns and a horizontal hydraulic press arranged horizontally between the middle of the columns. The motor of the hydraulic press is arranged on the upper part of the machine. A large flow low pressure pump group is added to the upper part of the machine to connect the vertical compression cylinder so as to make the cylinder move quickly. The electrical box and the control board control the operation of the machine through the computer. The utility model reduces the noise, and the deployment of each component is more compact and reasonable.

Elbow machine itself is a non-standard product, so there is no detailed specification model, we can directly customize cold push elbow machine according to customer requirements. Elbow diameter from 21mm-630mm, wall thickness is 3mm-30mm we can do. The main feature of cold push elbow machine is self-made cost. The positioning pipe fitting enterprise needs to purchase cold push elbow machine or elbow machine, which needs to be customized in advance. The company needs 60 days to make this equipment, and the elbow machine needs to be prepared for booking in advance.

The elbow produced by the elbow machine has a beautiful shape, symmetrical wall thickness and continuous production. Mainly can be produced in large quantities, and mainly push carbon steel, alloy steel material. If you need to produce stainless steel elbow, choose the cold push elbow machine produced by our company.

Elbow machine manufacturers after receiving customer orders elbow machine equipment, through the customer to provide the required elbow machine model and production material, elbow machine manufacturers to provide drawings to obtain customer satisfaction, in the manufacturing process will be completed together with customers, obtain customers in the company's trial machine and meet, transport to the customer only set within. In the transportation process, our company accepts large trucks or containers. Although the above mentioned containers will be used when exporting, container transportation will not be used in the sea, accepting large truck transportation will reduce the cost of customers, our company will transport according to customer requirements.

Usually order the company's pipe fittings equipment, our company will be implemented in the customer, our company in the order of the truck cargo container transport to the customer only set the location, in the installation row of the company's engineers and skilled staff to the customer's installation and commissioning, and how the customer is to our company's production of elbow machine operation and production process to provide the customer's operator staff. According to the things after the staff began production and processing after obtaining customer satisfaction after the skills of our company staff and engineers on the return trip to our company.

The pipe fittings and equipment produced by Aoguang company are transported to all over the world and obtained the satisfaction and recognition of users all over the world.

For more information about elbow machines, please visit our website: http://www.fitting-equipment.com

|