Intermediate frequency tube expanding machine manufacturers have many years of manufacturing inspection, usually in the company to order the expansion machine equipment users, our company will provide customers at a low cost, quality to meet the intermediate frequency tube expanding machine. The following is a brief introduction to the medium frequency pipe expanding machine:

In pipe expansion production, an automatically controlled medium frequency power supply heats the steel pipe to the desired temperature and keeps it constant. Especially in the thermal expansion of high-alloy steel pipes, it can better reflect the good and benign of the system to conform to the narrow thermoplastic deformation temperature area, which can prevent the excessive combustion of alloy steel pipes (high temperature) leading to the mass drop of steel pipes and the scrap of molds, and prevent the pull rod or mold fracture caused by the increase of the thermal expansion unit thrust caused by the low temperature. The stable operation of the thermal expansion unit is guaranteed, and the unstable factors are rejected.

The automatic constant temperature system of the medium frequency tube expanding machine combines the medium frequency power supply with constant temperature heating, and the heating of the tube is always in a constant temperature state. Compared with the artificially heated steel pipe, it is energy-saving and hygienic, simplifies the operation procedure, and reduces the labor cost. An operator can simultaneously monitor the normal production and expansion of up to 10 expansion units and pass pressure. Speed. Temperature programmed overload cover. Unstable factors caused by high pressure of pipe expansion unit.

Each group sets two temperature measurement points to automatically control the temperature. According to the preset heating temperature of the differential steel pipe, the heating temperature of the steel pipe to be expanded is selected and kept constant, which can be displayed and recorded in real time, and the real-time curve and history curve of the heating temperature parameters can be saved. The coherent temperature is automatically stored. Time. Thing pressure. Coherent information such as rate encapsulates the data.

The use effect of pipe expanding machine: This product equipment is commonly used in the production of various steel pipes. The pipe expanding machine accepts adjustable equipment, and the master cylinder thrust is designed according to customer demand. The steel pipe produced by pipe expanding machine has good sealing performance. High pressure pumps are used to perform high pressure tests. Medium frequency pipe expanding machine has reasonable device, high production efficiency and wide range of production specifications. Master cylinder thrust movable steel pipe, suitable for various lengths of steel pipe. Steel pipe is divided into seamless pipe, straight seam pipe, spiral pipe and so on. Pipe expanding machine equipment consists of: base, master cylinder support plate (including master cylinder), movable push plate, front support plate, automatic feed structure, feed roller table, mold support, IF coil adjustment frame (including if heating coil), if power supply, electrical control system, etc.

The tube expanding machine accepts the medium frequency power supply to feel the heating, and the wire deception is outside the steel pipe. Before the steel pipe is pushed, it is coated with lead powder and transported to the hydraulic push machine through the feed rack. After expanding the diameter, output through the feed rack. The main equipment is thermal expansion of steel pipes, mainly for the domestic production of large-diameter steel pipes can not meet the market demand and various steel pipe specifications design, to meet the production needs of small-batch multi-variety steel pipes, to meet the expansion of different materials and various non-scale steel pipe expansion needs, is the main production process of large-diameter steel pipes. It has been widely used in the military industry, power station construction, aerospace industry and Marine industrial equipment manufacturing industry, and has made great respect for the user's steel pipe industry and energy construction.

The pipe expanding machine automatically controls the intermediate frequency power supply during the pipe expanding production process, heating the steel pipe to the required temperature and keeping it constant, which prevents the steel pipe and mold from being scrapped due to the excessively high temperature of the steel pipe, and prevents the pull rod or mold from breaking due to the large thrust of the thermal expansion machine due to the excessively low temperature. Compared with the manual heating steel pipe, the operation procedure is simplified, the labor cost is reduced, and the normal production and pipe expansion of multiple pipe expansion units are realized.

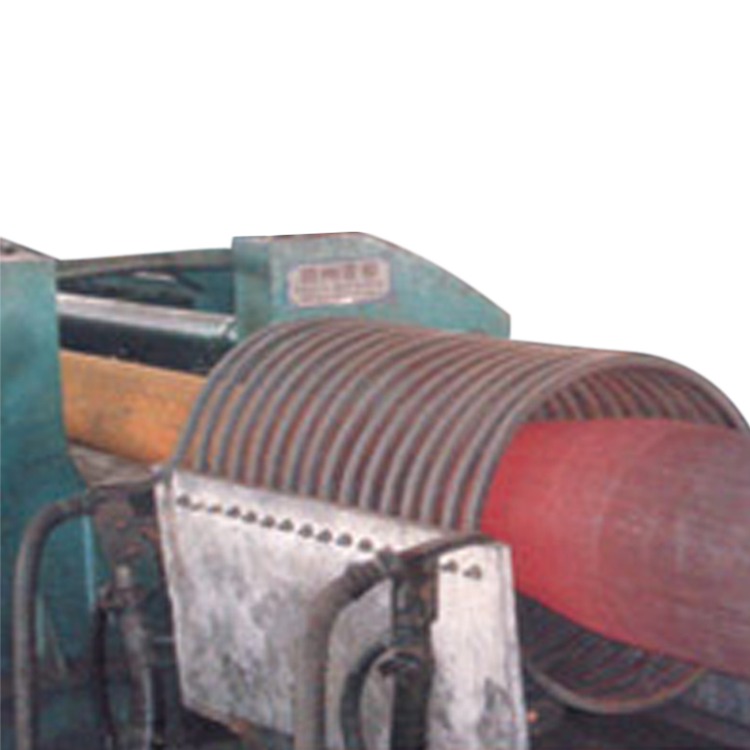

Our company developed a new energy-saving medium frequency tube expanding machine than the ordinary tube expanding machine 10%-35%, and achieved success. Structure of intermediate frequency tube expanding machine: tube expanding machine frame, hydraulic structure, intermediate frequency coil, core head, push plate, wheel bracket, electric reducer, hydraulic tightening structure, raw material mouthpiece, hydraulic roller and tightening guide structure.

The diameter of the medium frequency pipe expanding machine is 60mm-1420mm, the wall thickness is 3mm-120mm, the length is 3-24mm, and the steel pipe of various materials can be expanded.

The skill parameters of steel pipe flaring machine: flaring diameter: 60-1900mm, flaring wall thickness: 3-100mm (segmentation design and manufacturing equipment). Flared steel pipe length: 3-12m. The steel pipe expansion length is 1-1.5 times the diameter of the steel pipe.

Each set of two temperature measurement points automatic automatic temperature control, according to the pre-set heating temperature of the different grades of steel pipe, select the heating temperature of the steel pipe to be expanded and keep constant, and can be held real-time display and record, can print and survive the real-time curve of heating temperature parameters and history curve. At the same time, it will automatically store relevant information such as temperature, time, working pressure, speed, etc., to provide protection for the traceability of the data.

About the relevant knowledge of intermediate frequency tube expanding machine, welcome to pay attention to our website:http://www.fitting-equipment.com

|