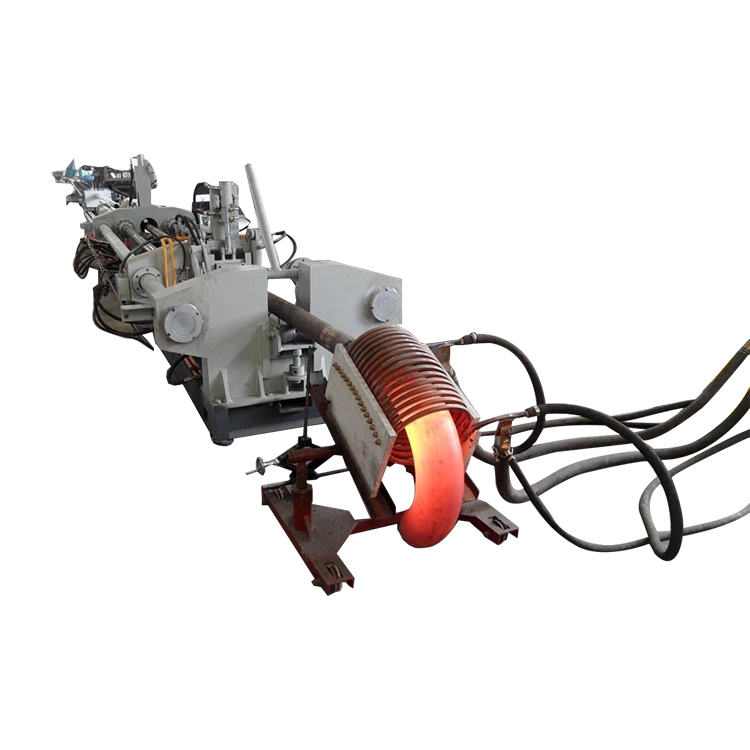

The head position of the elbow machine and the bed part of the reinforcement design, and after annealing treatment to eliminate internal stress, the whole has enough strength and rigidity. The transmission spindle is inserted directly from the upper part of the head during assembly, which is accurate in installation and easy in maintenance. The bending spindle and the transmission sprocket are cast, processed and hobbing as a whole without key connection, and the force is symmetrical, driven by double cylinders. During the bending process, the hydraulic system automatically saves buffer before the swivel arm is close to the bending set Angle, which greatly improves the bending accuracy and quickly resets There is a saving buffer near the starting point, which greatly improves the reset accuracy and work efficiency. Fully hydraulic drive, microcomputer controller can be preset 16 angles, the foot switch of the elbow machine can be used to complete the entire process at one time, hydraulic clamping, hydraulic pressing, hydraulic bending, hydraulic core-pulling, five cylinders (can increase the trolley feed and space corner efficiency). Elbow machine is mainly used for making elbow on air conditioning heating ventilation pipe.

The bending machine drive spindle is inserted directly from the upper part of the head during assembly, which is accurate and easy to maintain. The bending spindle and the driving sprocket are cast, processed and hobbing as a whole, no key is connected, the force is equal, and it is driven by double cylinders. During the bending process, the hydraulic system automatically saves buffer before the rotor is close to the Angle set by bending, which greatly improves the bending accuracy and fast reset. The return process is equipped with a saving buffer near the starting point, which greatly improves the reset accuracy and work efficiency. Full hydraulic drive. The microcomputer controller can be preset to 16 angles, using the foot switch of the elbow machine to complete the entire process flow at one time.

The elbow machine produced by Aoguang is mainly one of the necessary pipe fittings equipment for the production of elbow fittings, such as elbow machine, beveling machine, typewriter, sandblasting machine, etc., which will be used in the production of elbow fittings. Usually order the company's pipe fittings equipment customers the company at a low cost to allow customers to order excellent equipment. The materials produced by the elbow machine are divided into carbon steel, cast steel, alloy steel, stainless steel, copper, aluminum alloy, plastic, argon, PVC, PPR, RFPP(growth polypropylene) and so on. It can be divided into pushing, pressing, forging, casting and so on. It can be divided into national standard, electrical standard, ship standard, chemical standard, water standard, American standard, German standard, Japanese standard, Russian standard and so on.

According to its radius of curvature, it can be divided into long radius elbows and short radius elbows. Long radius elbow refers to its radius of curvature is 1.5 times the outside diameter of the pipe, that is, R=1.5D. Short radius elbow means that its radius of curvature is the outside diameter of the pipe, that is, R=1.0D. (D is the diameter of the bend, R is the radius of curvature). If it is divided according to the pressure level, there are about 17 kinds of pipes, which are the same as the pipe size in the United States, including: Sch5s, Sch10s, Sch10, Sch20, Sch30, Sch40s, STD, Sch40, Sch60, Sch80s, XS; Sch80, SCH100, Sch120, Sch140, Sch160, XXS; The two most commonly used are STD and XS. According to the different shape uses can be divided into: groove elbow, sleeve elbow, double bearing elbow, flange elbow, reducing elbow, dead seat elbow, surface tooth elbow, stamping elbow, push elbow, socket elbow, butt welding elbow, inner wire elbow, etc.

Elbow machine manufacturers to provide customer service is simple for each need to order pipe fittings equipment user service, know the customer's satisfaction. Elbow manufacturers guarantee the quality and production efficiency of the products, as well as the commissioning and installation of the elbow machine, our company's after-sales service will allow customers to get normal operation and production processing after installation and commissioning.

Elbow machine drive spindle is directly inserted into the upper part of the head, accurate installation, easy maintenance, elbow spindle and drive sprocket overall casting, overall processing, overall rolling teeth, no key connection, average force, driven by two cylinders, during the elbow process, the rotary arm near the bending set Angle before the hydraulic system automatically save buffer, greatly improve the bending accuracy, fast reset, Returning the process closer to the start saves buffering, greatly improving reset accuracy and things efficiency. Full hydraulic drive. The microcomputer controller can be preset to 16 angles, and the whole process can be completed by the foot switch of the elbow propeller. Elbow machine drive spindle is directly inserted into the upper part of the head, accurate installation, easy maintenance, elbow spindle and drive sprocket overall casting, overall processing, overall rolling teeth, no key connection, average force, driven by two cylinders, elbow process, the rotor close to the bending Angle before the hydraulic system automatically save buffer, greatly improve the bending accuracy, fast reset, save buffer close to the beginning, Greatly improve the reset accuracy and work efficiency. Full hydraulic drive. The microcomputer controller can preset 16 angles, and the whole process flow can be completed at one time through the foot switch of the elbow machine. The role of the elbow push machine is to play a major role in the production process of pipe fittings. The elbow machine can produce various elbows from different models, materials and angles. The materials produced by the elbow machine are: stainless steel, alloy steel, carbon steel, etc. The pushing Angle of the elbow machine is produced according to the requirements of customers. After the elbow, our elbow machine mainly accepts the hydraulic cylinder and advanced medium frequency power supply. We will wear energy saving and noise free medium frequency power supply according to customer requirements.

The elbow fittings produced by the elbow machine are suitable for elbow installation in pipeline construction. When assembling the spindle of the drive system machine tool of the elbow propulsion machine, the collet is inserted, the installation is accurate and the maintenance is convenient. After bending machine, long radius bend and short radius bend can be corrected.

About the relevant knowledge of elbow machine, welcome to pay attention to our website: http://www.fitting-equipment.com

|