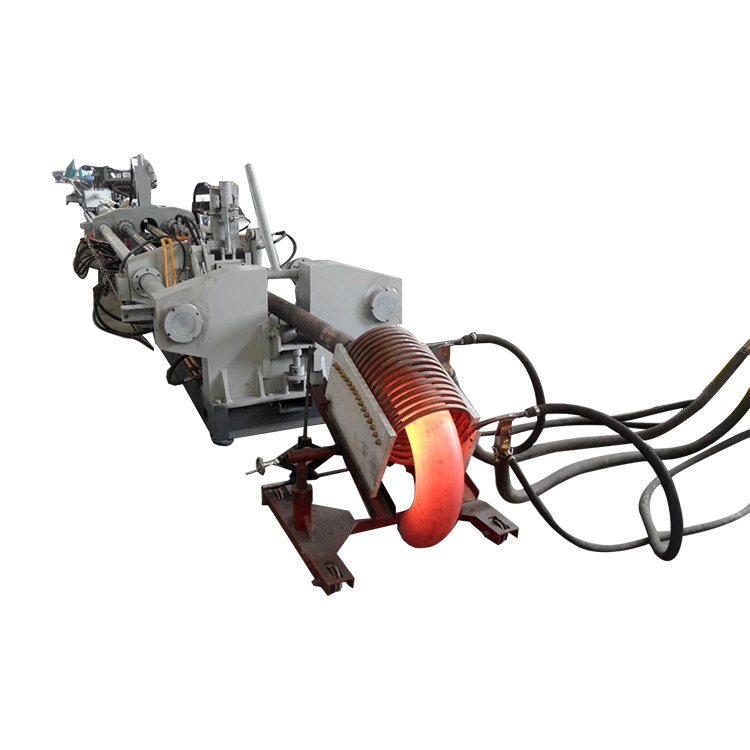

| An important tool in the pipe processing industry is the elbow machine, which is mainly used to bend straight pipes into the desired Angle and arc. Elbow machine has a wide range of applications in various fields, such as petrochemical, shipbuilding, power, water supply, heating and other fields, can not be separated from its application.

The production technology and quality control of the elbow machine is the key link in its manufacturing process, which is directly related to the quality and performance of the elbow machine, and also affects the operation and use of the machine. The following will be a detailed introduction to the production technology and quality control of elbow machine.

First, production technology

1. Design and manufacture

The design and manufacture of elbow machine is a step of its production technology, including the overall structural design of the machine, material selection, workmanship and other links. Modern elbow machine design and manufacturing generally use computer design and manufacturing technology, can carry out three-dimensional design and virtual manufacturing, greatly improving production efficiency and quality.

2. Material selection

Material selection is one of the key factors in making elbow. The main material of the general elbow machine is steel, and for the elbow machine required in different fields, different steels need to be selected. General factors to consider include the strength of the elbow mechanism material, corrosion resistance, machinability and cost. Therefore, material selection is an indispensable link in production technology.

3. Structural design

Elbow machine structure design is the most important part of elbow machine, it is related to the performance and operation of elbow machine. The structural design of modern elbow machine generally adopts numerical control design and virtual manufacturing technology, which can greatly improve the accuracy and efficiency of structural design, and also avoid defects in the manufacturing process.

4. Manufacturing process

The manufacturing process is a key link in the production technology of elbow machine, including material cutting, forming, processing, assembly, etc., in order to ensure the accuracy and quality of elbow machine. Modern production technology generally adopts automation and digital manufacturing, which can greatly improve production efficiency and is also conducive to stable improvement of product quality.

2. Quality control

1. Detection method

The key components of the elbow machine are inspected for size and density, including the size and hardness of the steel, as well as the internal and external surfaces of the elbow machine.

2. Quality control process

Quality control process is an important means to ensure the quality of products in the process of manufacturing elbow machines. Modern industry generally uses a variety of standards, according to the quality standards for process design, common quality management system certification such as ISO9001.

3. Verification control

Verification control is an important link in the process of manufacturing elbow machine, through the batch testing of product samples to verify the quality of the product meets the requirements, which is conducive to avoiding problems in the production process.

In short, the production technology and quality control of the elbow machine is a key technical work, and a good elbow machine needs to meet the requirements of all aspects, so it needs to be strictly controlled in the manufacturing process.

For more knowledge about elbow machine, please pay attention to our website:http://www.fitting-equipment.com

|