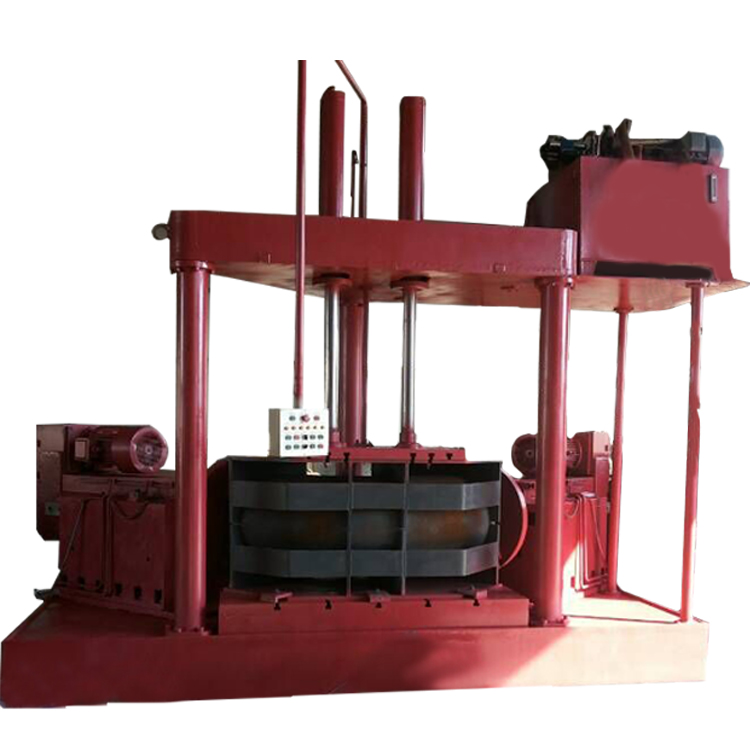

| Beveling machine is a mechanical equipment widely used in the processing of metal pipes. The beveling machine can be used to make various types of beveling, including V-shaped beveling, U-shaped beveling, Y-shaped beveling, etc. The main purpose of the beveling machine is to connect two pipes to form a longer pipe.

The beveling process of the beveling machine refers to some process details and precautions that need to be paid attention to when using the beveling machine. In this article, we will introduce the beveling process of the beveling machine in detail to help you make better use of the beveling machine.

1. Selection of beveling machine

Before beveling, it is necessary to select a beveling machine suitable for processing pipes. The selection of beveling machine needs to consider the material, diameter and wall thickness of the pipeline. If the selected beveling machine is not suitable for processing pipelines, it will lead to poor beveling or processing failure.

2. Determine the groove type

Depending on the purpose of the pipe and the connection requirements, the required groove type needs to be determined. The common groove types are V-shaped groove, U-shaped groove, Y-shaped groove and so on. Different beveling types require different beveling machines and process parameters.

3. Prepare the pipe

Before beveling, the pipe needs to be prepared. First of all, it is necessary to clean the impurities and oil stains inside and outside the pipeline to ensure the quality of the groove processing. Then it is necessary to measure the pipe diameter and wall thickness and other dimensional parameters in order to determine the processing parameters of the beveling machine.

4. Adjust beveling machine parameters

The parameter setting of beveling machine directly affects the quality and efficiency of beveling processing. Before beveling, it is necessary to adjust the parameters of the beveling machine according to the material, diameter and wall thickness of the pipeline. The main parameters include cutting speed, feed speed, tool number and tool Angle.

5. Machining groove

In the process of beveling, the pipe needs to be placed into the fixture of the beveling machine, and then the beveling machine is started to process. In the processing process, it is necessary to pay attention to the processing situation to ensure the quality of the groove production. If it is found that the groove is not made properly or the processing is abnormal, it needs to be stopped in time.

6. Finish the groove processing

After finishing the groove processing, it is necessary to check the groove after processing. It mainly includes the shape, size and surface quality of the groove. If the groove is poorly made or has defects, it needs to be repaired or reprocessed in time.

In short, the beveling process of the beveling machine is a crucial part of the beveling process. Through the correct selection of the beveling machine, determine the type of beveling, prepare the pipeline, adjust the parameters of the beveling machine, process the beveling and complete the beveling process, the quality and efficiency of the beveling processing can be guaranteed.

Related knowledge of the beveling machine, welcome to pay attention to our website: http://www.fitting-equipment.com

|