Elbow machine is a kind of mechanical equipment commonly used in pipeline processing, its main function is to bend metal pipes, steel pipes and other materials to meet different engineering needs. Among them, the performance of the elbow machine and the forming process have an important impact on the processing efficiency and the quality of the finished product. In this paper, the performance and forming process of the elbow machine will be discussed in detail.

First, the performance of the elbow machine

1. Structure of elbow machine

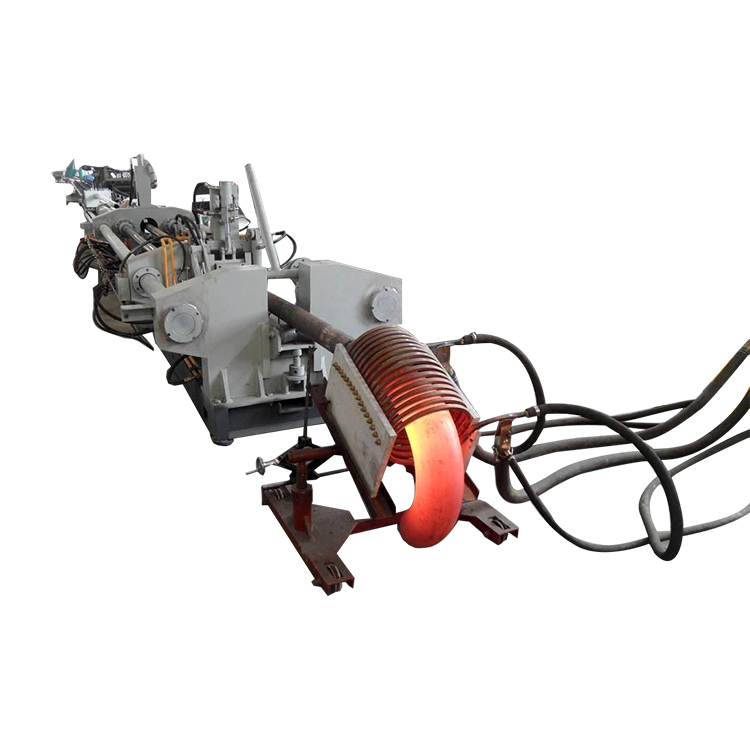

Elbow machine is generally composed of main engine, hydraulic system, electrical system, control system and so on. Among them, the main engine is the core component of the elbow machine, which is mainly composed of the fuselage, roll wheel, oil cylinder, etc. The fuselage is the support structure of the elbow machine, which is generally welded with steel plates and has sufficient strength and stability. The roller is the bending part of the elbow machine, which is used to apply bending forces and is driven by the bearing and gear transmission system. The oil cylinder is the power source of the elbow machine, which provides power through the hydraulic system and drives the roller for bending processing.

2. Bending capacity of elbow machine

The bending ability of the bending machine is generally measured by its bending radius, bending Angle, bending radius and the ratio of pipe diameter. The smaller the bending radius of the elbow machine, the greater its bending capacity, and the smaller the bending Angle can be achieved. The ratio of the bending radius to the diameter of the pipe determines the shape of the bend. In general, the larger the ratio of the bending radius to the diameter of the pipe, the gentler the bending shape.

3. Accuracy of elbow machine

The accuracy of the elbow machine is one of the important indicators of its performance, which is directly related to the quality of the finished product. The accuracy of the elbow machine is mainly determined by its control system, hydraulic system and roll. Among them, the control system is the key to the accuracy of the elbow machine, and the PLC control system is generally used to achieve the accurate control of the bending Angle, bending radius and other parameters. The hydraulic system is responsible for providing power and ensuring that the force applied by the roller is stable. The design and manufacturing quality of the roller structure is also one of the important factors affecting the accuracy of the elbow machine.

Second, the forming process of the elbow machine

1. Material selection of elbow machine

The material selection of the elbow is directly related to the quality of the finished product and the service life of the elbow machine. Generally speaking, the main material of the elbow machine should have the characteristics of high strength, high toughness, wear resistance, corrosion resistance and so on. Commonly used materials are cast iron, steel, fine steel and so on.

2. Pretreatment of elbow machine

The pretreatment of elbow machine is an indispensable step in forming process. Mainly including material cutting, deburring, polishing and other processes. Among them, cutting and deburring is an important step to ensure the forming quality of the elbow machine, and the surface of the material must be smooth, no burrs, no cracks, etc.

3. Forming process of elbow machine

The forming process of the elbow machine generally includes clamping, bending, straightening and other processes. Among them, clamping is the process of sandwiching the material between the roller wheel, and adjusting the position and bending Angle of the roller wheel. Bending is the process of applying force to bend a material into a desired Angle. Straightening is to correct the material after forming through the straightening roller or mold to ensure that the molding quality meets the requirements.

In short, elbow machine as an important metal processing equipment, has a very important role in modern manufacturing industry. The optimization of its performance and forming process is of great significance to improve the processing efficiency and ensure the quality of the finished product. The above is some basic introduction and technical points of the performance and molding process of the elbow machine, I hope to help readers.

For more knowledge about elbow machine, please pay attention to our website: http://www.fitting-equipment.com

|