Structure and working principle of Two-step Pipe Expanding Machine

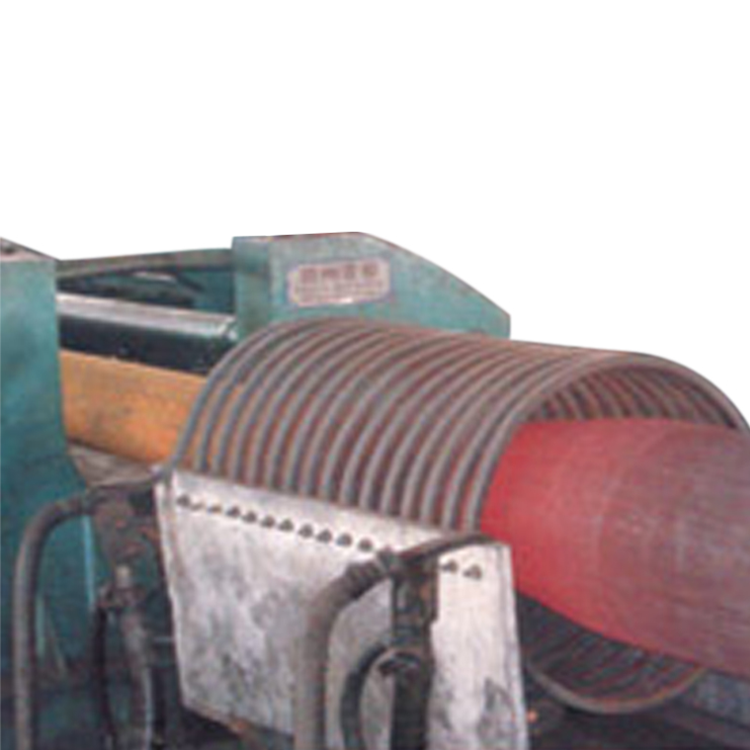

The structure and working principle of the two-step pipe expanding machine: the pipe expanding machine is a hydraulic push machine with two oil cylinders parallel to the average speed, and the valve table of the pump station adopts the integrated form. The feeding of the pipe expanding machine is driven by the coil yard machine to drive the wire rope, push the pipe through the wire rope wheel, work reciprocating, and send the original tube to the equipment.

The intermediate frequency power supply is installed in the front end of the pipe expanding machine, the if induction coil is placed on the coil adjusting frame, the coil is up and down, and the front and back can be adjusted. If the medium frequency power is adjusted, the core expanding die and pipe can be heated, and the pipe will be pushed forward slowly.

The pipe can be expanded by increasing the heating temperature to a certain temperature, resulting in plastic deformation and advancing along the outer diameter of the mandrel.

The controlled silicon, if coil, reactor and other components of the intermediate frequency power supply of the pipe expanding machine need circulating water cooling.

The electric control part of the pipe expanding machine is installed in the main control cabinet. The stroke switch is installed at both ends of the pipe expanding machine and the push plate is put in place and the automatic stop is made. |